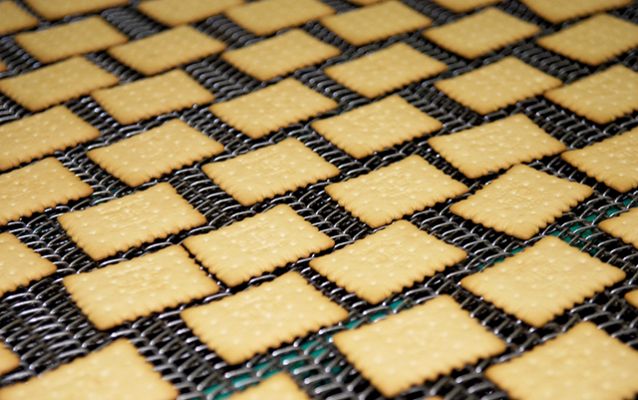

In baking ovens, after the “development” and the actual “baking” phases, at least one third of the oven length (the final section) is dedicated to “colouring and drying” the product.

As the product loses moisture, its thermal conductivity falls and evaporation slows. The evaporation is further compromised by the crust formation that acts both as a heat and mass transfer barrier.

The removal of the final excess moisture from the product is therefore a difficult task: the conventional oven finds it hard to transfer heat to the centre without the risk of over-colouring, which will result in a dark and out of specification product. Over-baking (browning) has also been recognised as one of the causes of Acrylamide formation, a suspected carcinogenic substance formed during cooking, baking and frying of carbohydrate-rich food products.

In July 2017, European Member State representatives voted in favour of a European Commission proposal to make it mandatory for food business operators to reduce the presence of acrylamide.

The new European acrylamide legislation 2017/2158 came into effect on April 11, 2018.

This is the stage where RF post-baking is of greatest value.

The RF electromagnetic field, due to its ability to transfer energy to the product volumetrically and Xively according to the moisture location, will overcome the low thermal conductivity and the crust heat barrier and directly dry the (wetter) centre of the product without affecting the desired colour.

Practically, combining a traditional oven with a post-baking RF equipment, it is possible to manage the baking process as follows: development, baking and colouring of the product will take place in the traditional oven, while the last phase of drying will take place in the RF equipment, with noticeable advantages in terms of energy saving, process time and final product quality.