Dryers for glass fibres

Stalam offers a wide range of Radio Frequency equipment specifically designed for the drying of glass fibres in various forms – mainly direct rovings, assembled rovings, yarns and chopped strands.

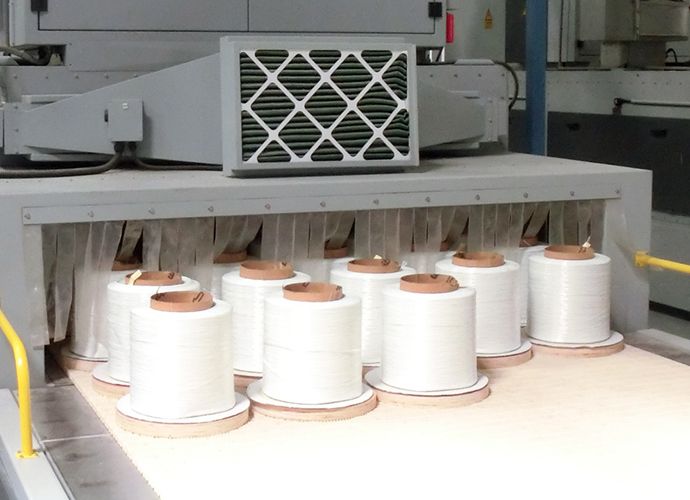

Precision-wound direct rovings weighing up to 35-40 kg each (approx. 18-22 kg according to industrial standards), placed vertically or horizontally on the RF dryer’s conveyor belt over suitable wooden or composite material holders – designed for the automated handling and transport systems used within the factory – can be dried down to a residual moisture content below 0.1% in a time range of approx. 2 to 4 hours (depending on the winding density and the fibre count) instead of the 20 – 30 hours usually required by conventional hot air circulation ovens. The longitudinal (transverse) expansion of the rovings during the process does not exceed 2-3 mm and there is neither migration towards the roving’s outer layers of the finishing chemicals (resins, starch, lubricants, etc.) nor the surface yellowing effect which is a typical drawback of conventional drying.

The residual moisture content of assembled rovings can be controlled accurately by a suitably adjusted Radio Frequency field, obtaining at the same time the ribbonisation of the fibres.

Chopped strands can be dried quickly and efficiently without any air movement, thus reducing almost completely the dust formation in the production department. Other glass fibre products, mainly in the form of bobbins and packages after various kinds of wet treatments, can be perfectly dried down to the desired final moisture content, efficiently and consistently, without any adverse effect on the finishing chemicals.

Production capacity from 2 tons/day to 40 tons/day each dryer. Stalam has successfully installed the world’s biggest RF dryers for glass fibre rovings, comprising of 6 drying modules in-line and having an overall length of over 30 m.

Continuous and in-line operation. Full product loading / unloading automation can be easily fitted.

70-90% shorter drying time compared to conventional systems, yet using less energy.

Consistent and thorough drying with no wet spots; no overheating, no yellowing, no migration of finishing chemicals.

TECHNICAL

Dryers for glass fibresRadio Frequency dryers for glass fibres in direct rovings, assembled rovings, yarns and chopped strands

Read more

Fiberglass drying

Fiberglass drying  Fiberglass drying

Fiberglass drying  Detail of the entrance to the dryer

Detail of the entrance to the dryer  RF dryer for fiberglass coils

RF dryer for fiberglass coils  Dryer for

Dryer for  Dryer for

Dryer for  Dryer for

Dryer for  RF dryer for glass fiber

RF dryer for glass fiber  Production of glass fibers

Production of glass fibers  Fiberglass drying

Fiberglass drying  RF dryer for fiberglass coils

RF dryer for fiberglass coils  RF dryer for glass fiber

RF dryer for glass fiber  RF dryer for fiberglass coils

RF dryer for fiberglass coils  RF dryer for glass fiber

RF dryer for glass fiber