TEXTILE

Dryers for loose stock, tow/top slivers and yarns in hanks

Textile fibres and yarns can be wet-processed (mainly bleached or dyed) in various ways and forms, according to convenience or to respond to specific requirements. Whatever the substrate, whatever the process, Stalam has developed the best drying solutions.

Benefits a glance Rapid and uniform drying

Rapid and uniform drying

Perfect residual moisture content control (+/-1%)

Perfect residual moisture content control (+/-1%)

No influence of atmospheric conditions on drying

No influence of atmospheric conditions on drying

No thermal or mechanical stress on fibres

No thermal or mechanical stress on fibres

No discolouring, no yellowing, no hairiness, no strength loss

No discolouring, no yellowing, no hairiness, no strength loss

More softness, better touch, minimum conditioning time

More softness, better touch, minimum conditioning time

Outstanding operational flexibility

Outstanding operational flexibility

Modular construction to meet every production requirement

Modular construction to meet every production requirement

User- and environmentally- friendly operation

User- and environmentally- friendly operation

In-line and just-in-time operation

In-line and just-in-time operation

Instantaneous start / stop (no need for pre-heating / cooling)

Instantaneous start / stop (no need for pre-heating / cooling)

Outstanding reliability even in harsh working environments

Outstanding reliability even in harsh working environments

Low overall running cost

Low overall running cost

TEXTILE

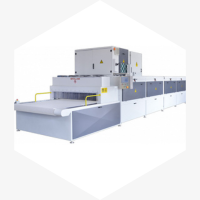

“RF” series dryers“RF” series for yarns in hank form, unwound tow/top slivers, loose stock and other “loose” textile products

Read more

TEXTILE

“RFA/S COMBO” Twin-Power series dryersRF and forced-air circulation combined drying equipment

Read more

TEXTILE

“LTRF” and “RFA/S” series dryers“LTRF” series dryers for the low temperature drying of all “loose” textile products

Read more

Radio frequency dryer for flake

Radio frequency dryer for flake  Drying of coils with radio frequency dryers

Drying of coils with radio frequency dryers  Drying cotton and rayon knitting yarn in skeins

Drying cotton and rayon knitting yarn in skeins  Radio frequency dryer for flake

Radio frequency dryer for flake  Radio frequency dryer for flake

Radio frequency dryer for flake  Radio frequency dryer for flake

Radio frequency dryer for flake  Radio frequency dryer for flake

Radio frequency dryer for flake  Drying of coils with radio frequency dryers

Drying of coils with radio frequency dryers  Radio frequency dryer for flake

Radio frequency dryer for flake